Overview

HWXE/PWXE

The CLARK HWXE/PWXE proudly carries on the legacy of the Powrworker Line, first introduced in 1920.With advanced operator ergonomics, durable construction, and a powerful 24V battery, the CLARK HWXE and PWXE set a new standard for electric pallet jacks.

Find Dealer

Features

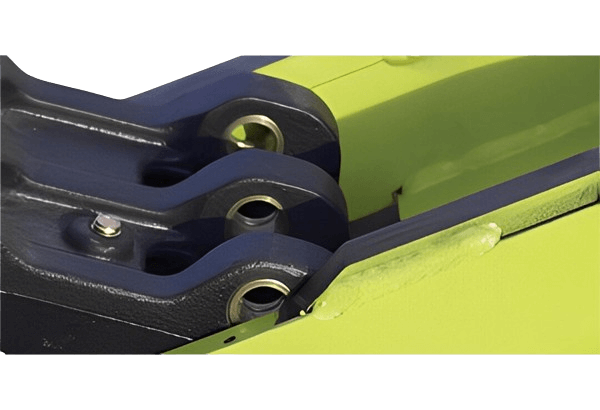

Lifting Mechanism

The HWXE is constructed out of the most durable and reliable components, designed to outlast even the toughest of applications. With adjustable pull rods that allow operators to maintain proper fork height for the life of the unit, extreme-duty bronze bushings, spring-loaded stability casters, and a solid steer bar design, the HWXE/PWXE sets the standard for durability.

Ergonomic Steer Handle

Operator comfort was at the forefront of the design of the HWXE/PWXE, which is evident in ergonomics of the steer handle. Handles are available with either a twist grip or thumb- operated control, giving your operators the flexibility to maneuver the truck in the way that will be most comfortable to them. The toggle switch on the control handle allows the operator to choose a low or high speed range based on the application. The PWXE requires minimal operator effort, with a low-mounted steer handle for increased leverage. The ample foot space on the HWXE is achieved with a top-mounted handle, giving operators the best of both worlds.

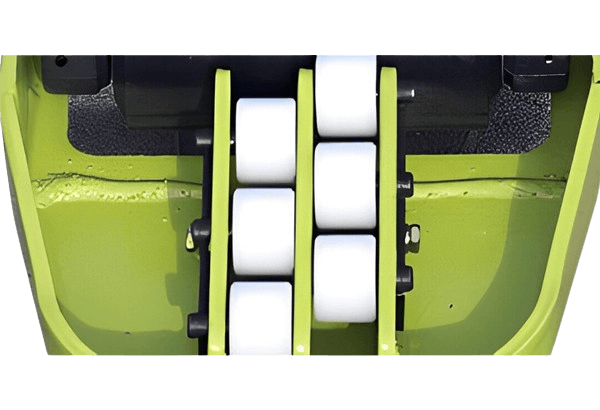

Pallet Entry/Exit

The entry and exit rollers on the HWXE/PWXE are designed to improve pallet entry and exit, along with the tapered sides of the forks. Smooth entry and exit from the pallet means fewer broken pallets, and less operational effort as operators navigate in and out of pallets. Exiting the pallet is clean and easy with the HWXE/PWXE rollers.

Hydraulic System

The hydraulic system on the HWXE/PWXE has a single-assembly design, with the integral pump, motor, and reservoir in one single assembly. These components do not require a breather cap, which eliminates a potential leak site and point where dirt can enter the system. This design protects the hydraulic system and promotes the longevity of your unit.

AC Drive Motor/Control

The 100% AC drive motor on the HWXE/PWXE is fully enclosed, which helps keep out dust and contaminants and ensures that a wet environment is not an issue, making the HWXE/PWXE the perfect choice for food service and cold storage applications. With no brushes to change or commutator to turn, ever, the HWXE/PWXE has a low overall cost of maintenance. And, with three forms of regenerative braking, the HWXE/PWXE is an environmentally- friendly and efficient machine.

Drive Unit

The drive unit on the HWXE/PWXE is quiet, and further promotes a low-maintenance operation. The spiral bevel gears are immersed in an oil bath and sealed in a heavy-duty case, maintaining the smooth operation of the truck shift after shift. And, the heavy ball bearing in the drive unit is specifically designed to withstand shock, meaning the HWXE/PWXE can tackle any task placed in its path.

Applications

Tech Specs

| Load Capacity / Rated Load (lbs/kg) | Height Overhead Guard (in/mm) | Width (in/mm) | Right Angle Stack (in/mm) | Outside Turning Radius (in/mm) | Inside Turning Radius (in/mm) | Top Speed Loaded (kmp/mph) | Top Speed Unloaded (kmp/mph) | Power Unit - HP(KW) @rpm | |

|---|---|---|---|---|---|---|---|---|---|

| HWXE 30 | 6000 / 2720 | 46.7 / 1187 | 36.0/32.0 | 914/813 | 76.2/82.2 / 1936/2088 | N/A / N/A | 6.4 / 10.4 | 8.4 / 13.5 | 24 volt |

| HWXE 40 | 8000 / 3630 | 46.7 / 1187 | 36.0/32.0 | 914/813 | 76.2/82.2 / 1936/2088 | N/A / N/A | 6.1 / 9.8 | 8.4 / 13.5 | 24 volt |

| PWXE 30 | 6000 / 2720 | 32.39 / 823 | 36.0/32.0 | 914/813) | 69.1/75.1 / 1755/1908 | N/A / N/A | 3.3 / 5.3 | 4.0 / 6.4 | 24 volt |

| PWXE 40 | 8000 / 3630 | 32.39 / 823 | 36.0/32.0 | 914/813 | 69.1/75.1 / 1755/1908 | N/A / N/A | 3.1 / 9 | 4.0 / 6.4 | 24 volt |