Overview

CGC 40-55 Series

The CGC40/50/55 series proudly adds to our unique history of building the best forklifts with evolutionary steps in ergonomics, power, safety, durability, and performance. These models, designed for distribution, manufacturing, and warehousing of all types, are suited for the toughest applications.

Find Dealer

Features

Upright & Carriage

The lift cylinders, chains, and hoses in the CGC40 series are all mounted within the rail profile for maximum visibility. The silent staging of the hydraulic cushioning valve reduces shock and vibration. The carriage has 8 shimmable, sealed, and canted rail rollers and 4 side thrust rollers to maximize load distribution and reduce free play.

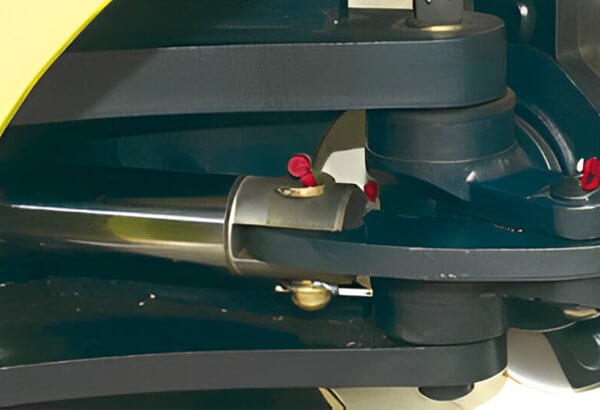

Steering Axle

The field-tested steering axle on the CGC40 series is designed with a rugged “double sheer” design to withstand impact without loosening or breaking. The simple, double-ended cylinder design provides additional steering force, which makes maneuvering the CGC40 simple.

Hydraulic System

The CGC 40/50/55 series hydraulic system uses a load-sensing flow control valve for steering to reduce heat build-up and operate with maximum horsepower. The main hydraulic valve incorporates adjustable flow controls for tilt and auxiliary functions. The sectional design allows for the easy addition of extra functions which simplifies service. The upright-mounted load lowering valve allows for controlled lowering, independent of engine speed.

Operator Compartment

The CLARK CGC40 series comes equipped with a fully adjustable, full-suspension seat, molded for support with a non-cinching, retractable seat belt. The tilt steering column can be adjusted to suit the operator and provides easier exit/entry. The fingertip control option allows for ergonomic operation. Finally, the thick molded floor mats are designed to reduce vibration and noise level to improve operator comfort.

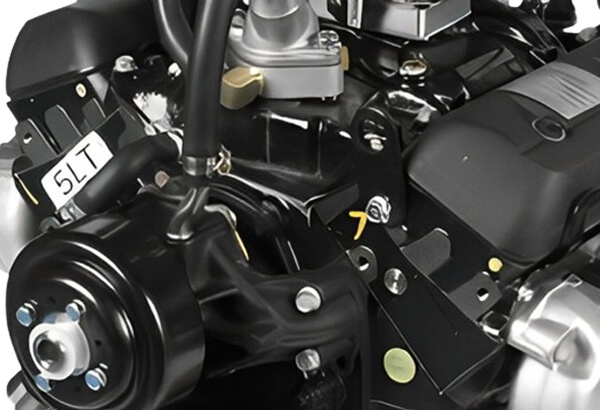

4.3L PSI-4X LPG Engine

The field-proven 4.3L PSI – 4X LPG Engine is built for smooth, quiet operation and comes with an auto shut-down feature which helps you protect your investment in the event of excessive engine coolant, high transmission oil temperature, or low engine oil pressure. A visual warning light illuminates to warn operators of low oil pressure levels. You can access the engine compartment in less than 30 seconds with no tools required. The system can be diagnosed using an automotive-style malfunction light and fault codes. The engine has a computer-controlled fuel system and has hardened exhaust and intake valves which lengthens the lifespan of the truck.

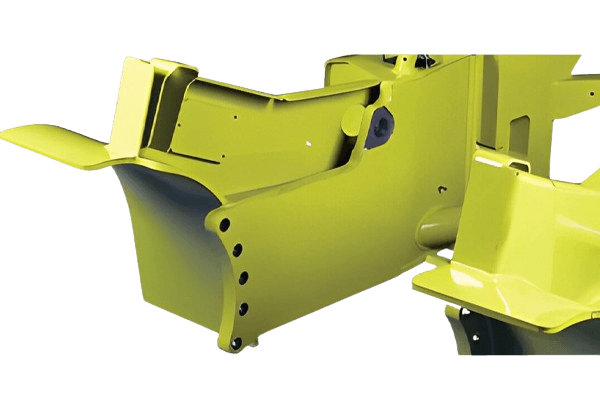

Built to Last Frame

The frame on the CGC40 series has no exposed seals or driveshafts to wear or collect debris. The modulated shift protection ensures smooth engagement and cushioned shifting. The common sump for the axle and transmission lube allows both to be cooled with the transmission cooling system. The inching valve allows for precisely controlled travel speeds during high-speed lifting.

Brakes

The brake system on the CGC 40/50/55 series is simple and easy to use. The brakes are applied with a hydraulic servo-type power brake valve. The transmission also disengages when the parking brake is set, preventing the operator from driving against the brakes.

Applications

Tech Specs

| Load Capacity / Rated Load (lbs/kg) | Height Overhead Guard (in/mm) | Width (in/mm) | Right Angle Stack (in/mm) | Outside Turning Radius (in/mm) | Inside Turning Radius (in/mm) | Top Speed Loaded (kmp/mph) | Top Speed Unloaded (kmp/mph) | Power Unit - HP(KW) @rpm | |

|---|---|---|---|---|---|---|---|---|---|

| CCG40 | 8000 / 4000 | 87.2 / 2215 | 50.8 (1290) | STD 106.7 (2710) / TSU 107.5 (2731) | 89.4 / 2270 | N/A / N/A | 12.2 / 19.6 | 12.5 / 20.1 | PSI-4X 4.3L 110 (82) @ 2400 |

| CGC50 | 10000 / 5000 | 87.2 / 2215 | 54.8 (1392) | STD116.0 (2946) / TSU 116.8 (2967) | 98.2 / 2494 | N/A / N/A | 12.1 / 19.5 | 12.4 / 20.0 | PSI-4X 4.3L 110 (82) @ 2400 |

| CGC55 | 12000 / 5500 | 87.2 / 2215 | 54.8 (1392) | STD 118.3 (3005) / TSU 119.1 (3025) | 99.9 / 2537 | N/A / N/A | 11.7 / 18.8 | 12.2 / 19.6 | PSI-4X 4.3L 110 (82) @ 2400 |